According to Allied Market Research, the global interbody fusion cage market was valued at $1,818 million in 2016, and is expected to reach $2,309 million by 2023 at a CAGR of 3.4% during the forecast period.

Rise in geriatric population and increase in incidences of spinal injuries and sports injuries drive the growth of the market. In addition, surge in demand for interbody fusion cage surgeries due to advantages that allow the surgeon to directly decompress nerves and reconstruct the spine further fuels the market growth. However, high costs associated with spinal fusion surgeries, lack of trained professionals as well as stringent rules & regulations to use these devices hamper the market growth. Moreover, the launch of novel interbody fusion cages with new compatible materials create more opportunities in the market.

Thes interbody fusion market according to the material is still dominated by PEEK but with a strong trend towards porous materials and especially titanium.

How many Devices compete in this market?

There are at least 32 different TLIF porous Cages. Please to know more visit:https://thespinemarketgroup.com/category/3d-ifc/

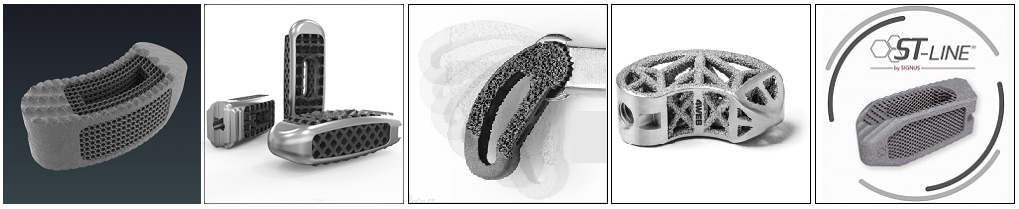

Today, we have selected 10 Porous Titanium PLIF/TLIF Devices that have been launched recently and probably are not as known as their deserve according to their features and benefits that they provide (in Alphabetical order):

1.- ARIES TC | OSSEUS

Aries™ interbody fusion devices feature a proprietary multi-axis mesh and optimized micro-surface topology, both of which are designed to facilitate fusion. The product’s lattice helps increase the implant’s porosity to 80%, which provides unparalleled in-situ radiovisibility compared with other titanium implants. The implant’s anatomic profile, anti-migrational teeth, and streamlined insertion are designed to increase procedural efficiencies.

For more information please visit:https://osseus.com

2.- F3D Curved | CORELINK

The F3D Curved interbodies leverage the benefits of Mimetic Metal® technology which emulates key characteristics of natural bone to provide an optimal structure and environment for healing.

- 100% open-pore architecture to allow for osteointegration

- Hydrophilic wicking

- 3D printed titanium with 70% porosity

- Large graft window

- Provided sterile

For more information please visit: https://corelinksurgical.com

3.- 3D Printed TLIF |Global Biomedica

This TLIF Cage has been manufactured in biocompatible titanium (Ti64ELI) with the latest 3D printing technology DMSL (Direct Metal Laser Sintering).

Internal and surface grid structure (Cube vertex centroid – lattice) with reinforced edges ensures not only high stability and resistance to deformation of the cage, or immersion in the vertebral body, but also bioactivity – potentiates the formation of bone in the area of contact surfaces and thus the formation of a strong connection between the cage and bone, the risk of developing nonunion ( pseudoarthrosis ) is thus minimized. This property is particularly outstanding when compared to the widely used PEEK implants (poly-ether-ether-ketone).

TLIF range includes 54 size types ( 9 different heights – 7 to 15mm, and two different angles of lordosis). Thus, a wide range of modern tools for simple and, if necessary, minimally invasive cage insertion was designed.

For more information please visit: https://globalbmd.com

4.- Hexanium TLIF | SpineVision

The Hexanium TLIF cage is a 3D printed interbody system made of titanium. The titanium rough surface & optimized porosity of the cage enhance a strong primary integration & optimal bone in-growth. The Hexanium TLIF honeycomb structure provides a well shared resistance allowing a large vizualisation window & large bone graft chamber to reduce the risk of subsidence.

Please for more information visit: http://www.spinevision.net

5.- IdentiTi | Alphatec

Fully Interconnected Porous Architecture Titanium Interbody Implant Portfolio including: TLIF, PLIF, Lateral , ACDF and ALIF cages.

Key features include:

- Consistent, fully interconnected porosity throughout the implant designed to mimic the structure and porosity of cancellous bone;

- Proprietary pore structure designed to create surface roughness that enhances immediate implant stability and facilitates surface adhesion;

- Reduced density (60% porous) enhances intraoperative and postoperative imaging;

- Stiffness similar to bone;

- Subtractive manufacturing process creates a consistent porous titanium material that furthers product performance predictability with consistent and reproducible interconnected pore sizes across the IdentiTi family of implants; and

- Intuitive, low profile, and exacting instruments designed to optimize the surgeon experience and facilitate outstanding patient outcomes.

Please for more information visit: http://www.alphatecspine.com

6.- MATRIXX | NEXXT Spine

NEXXT MATRIXX System is a collection of 3D printed porous titanium interbodies that leverages Nexxt generation technology to create interbody and VBR devices with optimized open architectural porosity, residue-free surface technology, and robust radiographic imaging performance.

Features:

- The NEXXT MATRIXX® porous titanium material exhibits a varied 300, 500, and 700µm pore architecture

- Highly cohesive 7µm roughened topography

- Large 700µm lateral pores within the 75% open porous architecture minimize titanium material for an overall reduced density thereby facilitating enhanced radiographic imaging and post-operative fusion evaluations

Please for more information visit: http://www.nexxtspine.com

7.- NEST | BIOMECH

NEST Interbody System is a hollow, rectangular implant that consists of a unique configuration of both solid and porous structures, which are built using Paonan’s 3D printing Titanium technology.

Bone In-Growth with Nest generation

- Interconnected Porous Structure

- Titanium Dioxide Layer and Rough Surface

- Diamond Lattice / Solid Framework Composite Architecture

- Serrated Surface Design

- Smooth Wedge-shaped Design

Please for more information visit: www.biomech-spine.com

8.- TirboLOX-L | Captiva Spine

Captiva Spine’s TirboLOX (Titanium Reinforced Bone) titanium lumbar (TLIF and PLIF) interbody cages are created using an advanced 3D printing technology. This is an additive manufacturing process that enabled TirboLOX implants to have unique surface features and structures not possible with traditional machining. Purposely designed to potentially promote a strong interface between metal and bone (biologic fixation) TirboLOX incorporates:

- Surface roughness (with peaks and valleys) outside and inside the implant

- Interconnected organic lattice structure featuring a dual layer of varying porosities

- Open architecture to reduce radiographic presence for clear imaging

Features (TLIF):

- 3D Printed Titanium Alloy (Ti-6Al-4V)

- Heights ranging from 8-16mm in 1mm increments

- Length: 30mm

- Lordotic (6° of Lordosis) and parallel profiles

- Pivotec® Technology – Articulating Cage Delivery

Please for more information visit: http://www.captivaspine.com

9.- TRUSS | 4WEB Medical

4WEB Medical’s 3D printed technology utilizes engineering principles such as structural mechanics and adjacent material reaction to produce innovative spine implants that may actively participate in the healing process.

Benefits:

- Unique implant surface texture reduces the chance of migration.

- Load distribution reduces stress risers and subsidence-related complications.

- Open architecture allows for up to 75% of the implant to be filled with graft material to maximize bone incorporation.

- Truss design limits imaging artifact.

- Bi-convex surface brings implant closer to adjacent bone.

Please for more information visit: https://4webmedical.com

10.- WOMBAT ST | SIGNUS

WOMBAT ST consists of a titanium grid structure that, with its defined pore design, imitates the architecture of natural bone. The interconnectivity of the pores ensures optimal oxygen and nutrient supply, creating an optimized basis for bony ingrowth. The implant also offers more room for fusion, with 70 % of WOMBAT ST consisting of pores. The roughness of the implant – in addition to its proven SIGNUS teeth design – optimizes the primary stability and counteracts migration of the implant. In addition, the lateral surfaces are embedded in a smooth frame in order to keep the amount of preparation needed low and to protect the nerval structures during implantation.

Please for more information visit: http://www.signus.com/intl/